Adding Ultrasonic Cleaning to their restoration company has added new profit centers.

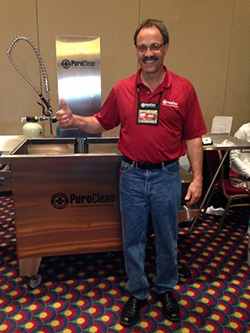

Mark Mazzoleni, owner of a Puroclean franchise in Green Bay, Wisconsin was struggling with fire restoration jobs. The hand cleaning work his staff was doing was too time consuming and not enough jobs were coming in. Mark also wanted to diversify his services and keep his staff busy when they were not busy with fire work. In 2011, he began researching Ultrasonic Cleaning as a possible way to achieve his goals.

“I began looking for used Ultrasonic equipment to get started, and purchased two Morantz tanks in May 2011. One of these tanks was for content restoration and the other was a blind cleaning machine,” Mark said. “I liked the idea of offering a service for blinds and saw that as a real profit center, which ultimately it has proven to be.”

Mark soon realized that these two tanks were going to be helpful to get started, but were not going to allow him to process the quantity of Contents he was beginning to bring in. This is when he started looking into the Morantz M-115 Super System. “Once I realized how streamlined the Pre-Wash, Ultrasonic Wash, Rinse and Dry stations were, I decided to jump in and purchase the entire Morantz Super System. It was the best decision!“.

Mark tells us that his employees absolutely love using the Super System. “Once my staff saw how easy it is to use the equipment to do their job, they were 100% on board“, states Mark. He continues, “One of the best things about working with Morantz is their unlimited, free training. I’ve had staff turn-over in the past 3 years, including my Contents Manager. Morantz will train as many people as I need them to. I’ve sent staff members to Philadelphia for training, and most recently we’ve even done training by Facetime over the iPhone, which was incredible!”

Mark continues, “The training sets the tone of the relationship with Morantz. My staff knows that if they have any questions, they can call Morantz and get answers. I’ve called myself quite a few times, and each time I get the support I need from Lisa, Heather and the Morantz staff. Joe Leggett, Morantz’s longtime employee of 35 years, knows me by name and is always happy to answer my questions.”

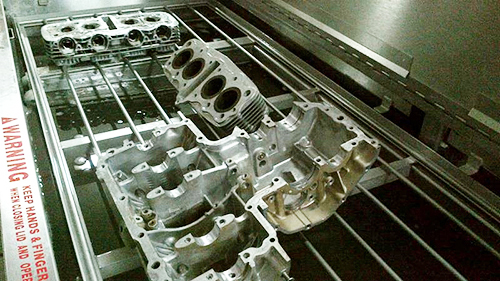

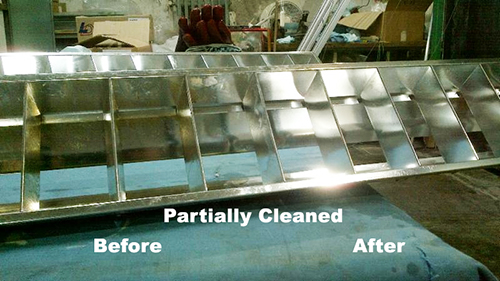

Mark recently presented his Ultrasonic cleaning service to a large company in the Green Bay area that rents equipment to disabled, home-bound people. They needed a method of both cleaning and disinfecting these items to be able in order to rent them out again. “I initially received CPAP machines and oxygen tanks test clean and deodorize. The company who rents these struggled because even though you are not supposed to smoke while using these devices, people do. Nicotine and smoke odor permeate the devices, and no matter what they had tried, they could not get these items clean. They were thrilled when I presented Ultrasonic Cleaning as a solution.” Below are pictures of these items.

Congratulations to Mark and Puroclean. Best wishes for their continued Success.

From November 19 -21, we’ll be exhibiting at the

From November 19 -21, we’ll be exhibiting at the

Thanks to all for making our 75th year of business a great success. Our last and BEST anniversary special still going on until December 31. Check out our new logo commemorating our long years of business history.

Thanks to all for making our 75th year of business a great success. Our last and BEST anniversary special still going on until December 31. Check out our new logo commemorating our long years of business history.