When it comes to cleaning Automotive Parts, the Ultrasonic process does an exceptionally good job. Whether it is grease, dust, rust, carbon, or other dirts, in most cases, these can be removed quickly and easily without hours of hand scrubbing or use of harsh chemicals.

I wanted to share with you some pictures from recent jobs that we’ve done.

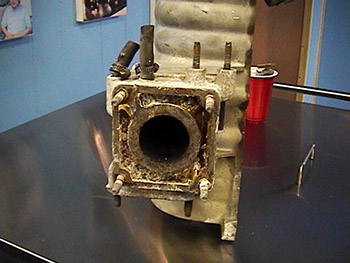

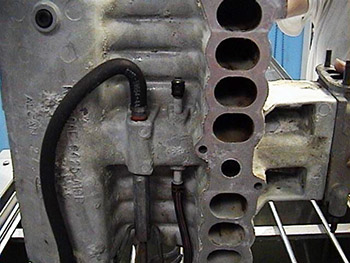

Most recently, I had a client visit and he brought with him an intake manifold from a Ford Mustang engine. He was specifically looking for a way to clean parts prior to powder coating them. Here are the “before” pictures:

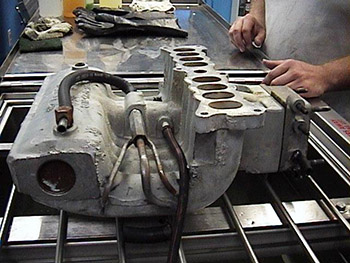

Here are photos of our client checking out the finished result:

Depending on the type of dirt we are dealing with, and the make up of the parts to be cleaned, we may work with either a 40kHz frequency (our standard) or a 25kHz frequency to get more aggressive. The rule of thumb is that the lower the frequency, the larger the bubble that is being produced and the more powerful the implosion in the Cavitation process. We also have 4 different cleaning solutions that we utilize depending again on the dirt and the part.

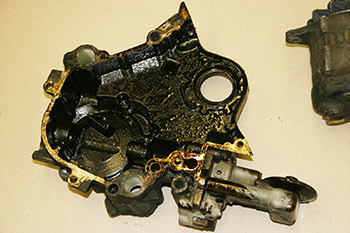

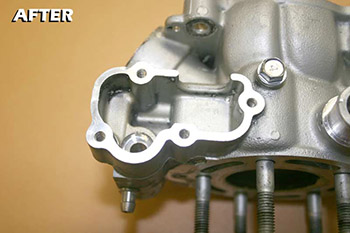

Take a look at the following before and after photographs of other automotive parts we have cleaned with Ultrasonics:

A few of the parts you see above are piston heads and exhaust lifters from a motorcycle. There are also rims from a Nascar race car. We have similarly cleaned helicopter parts, boat parts, airplane parts and more. Next week we will be trying something new…lawnmower parts…so check back soon.