Electronics Cleaning is an industry in its infancy, but Morantz has been cleaning electronics with ultrasonics for over 30 years. Our customers are way ahead of the curve when it comes to this niche market, and have been cashing in. If you are still surprised that you can clean electronics and electrical appliances with ultrasonics (yes, in water!), and want to learn more about how to clean Electronics with Morantz Ultrasonics, read on.

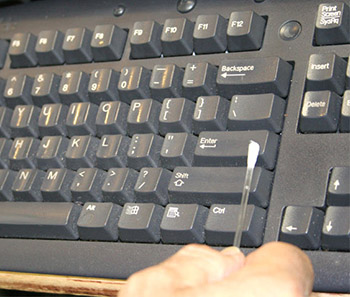

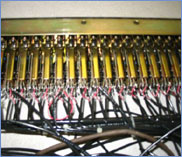

The Market: Today, nearly every aspect of cleaning brings us in contact with electronics. Homes, offices and facilities contain some combination of desktop computers, laptops, tablets, game consoles, music players and equipment, electronic musical instruments, printers, telephones, toys and more. These items cannot be ignored, especially when it comes to serious and deep cleaning for smoke, soot, water, mold and disinfection. Many cleaning services will shy away from electronics and give the job (and all the profit) to subcontractors. The reality is that if you have an ultrasonic machine, a proper drying room/drying cabinet, and instruction from Morantz, you can clean electronics.

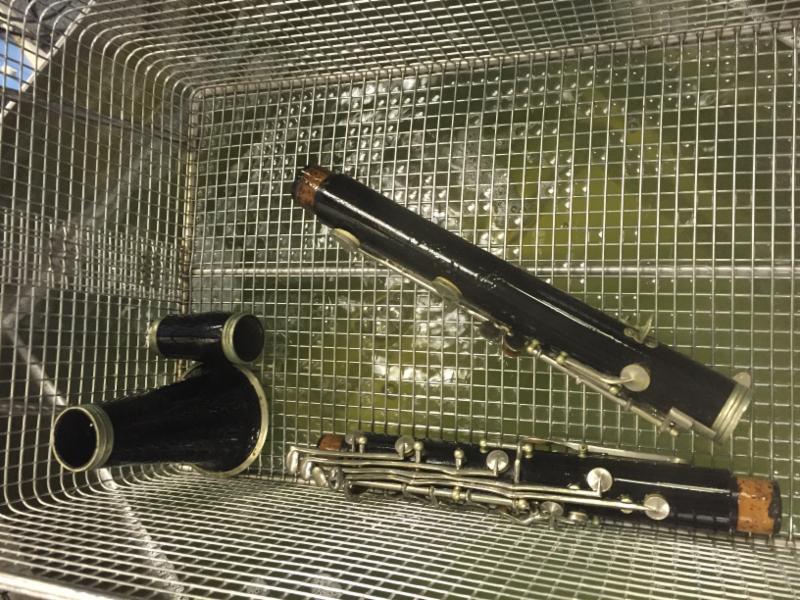

Our customers using their machines to clean electronics are doing very well. This niche market goes well beyond restoration work and has opened the way to cleaning set top cable boxes, maintaining expensive industrial coffee and food dispensing machines, cleaning headsets for phones, cleaning power tools, cleaning electrical musical instruments, disinfection of medical equipment in hospitals, and so much more.

The Process*: Remove the electronic item’s cover and any batteries, if applicable. For computers, remove the hard drive. Pre-wash if needed. Ultrasonic clean for 1-2 minutes. Rinse with deionized water. Dry immediately and thoroughly with the Morantz Blow Dry Gun. Spray with Morantz Miracle Chemical to displace any extra moisture. Place in the Morantz Drying Cabinet (or equivalent drying room with proper temperature, relative humidity and air flow) for a minimum of four hours.

For Disinfection: If you have Morantz equipment, you already know our equipment has been tested and proven for disinfection if used properly. Ultrasonic clean for a minimum of 3 minutes in your Morantz machine (results not proven for other manufacturers). Check your cleaning work with an ATP meter. This will let you know if there is still anything “live” on the electronic item that could be viral, bacterial or otherwise problematic. Then follow all other steps above.

For On Site Cleaning: Customers with sensitive information may not allow for their computers and other electronic equipment to leave their site. All Morantz ultrasonic machines are built on wheels and can be taken to the job site. However, the most portable and least costly machine is the Z-56. For drying, we recommend building a temporary drying room using a dehumidifier, space heater (if necessary) and an air mover. Be sure the drying room still meets proper parameters for temperature and relative humidity. To see photos from one of our on site computer cleaning jobs on our Facebook page, click here. For this job we used plastic sheeting to build a temporary drying space in one corner and it worked very well.

Equipment: Every Morantz model of machine can be used for electronics cleaning, but our most popular models are the SM-200 and M-115. These machines have electric lifts that make cleaning electronics easier for the operator. There’s no heavy lifting or awkward handling of items involved. For drying, our Drye-Rite drying cabinet with ozone is ideal.

*There are additional steps for specific types of electronics. This article does not take the place of training. Training is free of charge to all Morantz customers. If you want to learn more, be sure to click through all the links and contact your Morantz representative at 215-969-0266.

More photos: