At Morantz, we take a different approach to training than what’s typical for the industry. We prefer to keep it a little “old school,” with an emphasis on hands-on, individualized attention. Over the years we’ve found that this approach results in students who are far better trained and ready to be productive. You can see this on display in this post. Below, we feature just a few of our clients who have either visited us at our headquarters in Philadelphia or had us visit with them at their location for on-site training.

Now, that’s not to say we don’t keep up with the times. We’ve recently held several, very successful online webinars and are planning more, but there’s something about spending that quality, face-to-face time with our customers that sitting in front of a computer just can’t duplicate. That’s one of the reasons we built a new, state-of-the-art training center at Morantz HQ, and we’re ready to start filling those seats (learn more about our new training center below)!

In the meantime, scroll down to learn more about our training (or click here), and meet some of our successful students. There’s a reason why they’re smiling. Can you guess why?

Did you know that training is free of charge at Morantz Ultrasonics? This has been the Morantz policy for over 55 years, and it’s not changing. According to Lisa Morantz, President of Morantz Ultrasonics, “Our customers invest in equipment to make their businesses profitable, but owning the equipment is only one half of a winning formula. Equally important is having personnel that “buy in” and are excited to use the machines. They need to know how to properly operate the equipment, and know who to ask for assistance when questions arise. This is why training and support is always free of charge, and I encourage every one of our customers to take advantage of it.”

The free training we offer at our Philadelphia World Headquarters has long been one of our most popular services. Now, with the opening of our new training center (affectionately known as Morantz University, or “Morantz U“), we’re looking forward to seeing our clients come for a full day of hands-on training where they learn things like how to properly set-up, use and maintain their Morantz Ultrasonic Cleaning Systems. “It’s a fun, interactive day,” said Lisa Morantz. “We work one-on-one with our customers to make sure they have our undivided attention, that their questions are answered,and that they leave with a tremendous feeling of confidence and the skills they need to use their machines.”

While we certainly want to fill those seats, we know that a trip to Philly isn’t always possible. For those who can’t make the trip, who can’t send their entire staffs or who have specific and specialized needs, the best alternative is to have a Morantz Certified Trainer come right to their facility (for a reasonable fee – call (215) 969-0266 for details). This was the case for one of our long-time clients, York Caskets, a division of Matthews International.

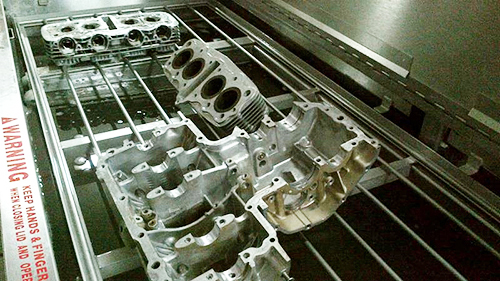

York purchased their Z-97 in 2007 to clean very specific parts used in the manufacture of caskets. Morantz had worked with York to develop specialized cleaning procedures and York sent staff to Philadelphia for training. However, just a few years later, York had a lot of new employees who were struggling with the machine. After a quick call to Morantz, we visited them at their facility and held a comprehensive training session for 10 of their new employees.

“When the trainees see the amazing results and understand how easy their work can be when the process is done properly, they begin to relax and have fun with it,” says Robby Zeaman, a Morantz Ultrasonics Certified Trainer.

Cleaning Specialized Parts in Their Z-97 “Brother.”

“If the people you’re training feel comfortable with you, they will feel comfortable reaching out to you again with their questions,” added Zeaman. “It’s so important that they know they have someone to answer these questions. The machines aren’t hard to use, but there are some specific things the operators need to know to get good results. If they get frustrated, they’ll give up and go back to whatever outdated and inefficient method they were using. It defeats the purpose.”

In addition to training equipment operators, Morantz also provides Business and Marketing Training. For example, at a recent on-site training at Servpro of West Kirkwood in Missouri, Lisa Morantz not only spent much of the day training the Contents Restoration staff, she also took time to work with their marketing department to review advertising tactics and to discuss how to pursue some new opportunities that have opened up.

Finally, Morantz made a presentation to the Continuing Education class being held at Servpro that same day. Jeff Chestnas (Servpro owner) told Morantz that he was thrilled that she incorporated a live demonstration, plus a fun and dynamic question and answer session. He believes Lisa’s presentation had an immediate benefit to his business.

Morantz has also worked directly with customers helping them clean their very first jobs. What a great way to train!

Lisa Morantz tells us, “There’s nothing like having your staff jump right in with their first job and see immediate results. They get excited and it goes a long way in building their confidence.”

Finally, for those who don’t have the budget to either visit with Morantz or have an on-site trainer visit them, Morantz is now offering a training session on Facetime through the iPhone/iPad. Clients can schedule a time for Morantz to call, and a Certified Trainer will talk the staff through the use of the equipment. This service is also provided free of charge.

If you would like to learn more about Morantz Ultrasonics training, call us at (215) 969-0266. We look forward to hearing from you.

One of the challenges of space missions is keeping clean. While personal hygiene is difficult enough in space, future missions to the Moon and Mars are going to encounter another, very difficult cleaning problem; dust contamination.

One of the challenges of space missions is keeping clean. While personal hygiene is difficult enough in space, future missions to the Moon and Mars are going to encounter another, very difficult cleaning problem; dust contamination.![Astronaut Gene Cernan on the Moon in December 1972. His spacesuit is blackened by lunar dust. According to NASA, “a real hazard that might have caused hatch and spacesuit seals to fail on a longer surface mission.” [NASA/JSC]](https://ultrasonicmachines.com/wp-content/uploads/2014/01/Gene-Cernan-on-the-Moon.jpg)

From November 19 -21, we’ll be exhibiting at the

From November 19 -21, we’ll be exhibiting at the